PRODUCTS CATALOG

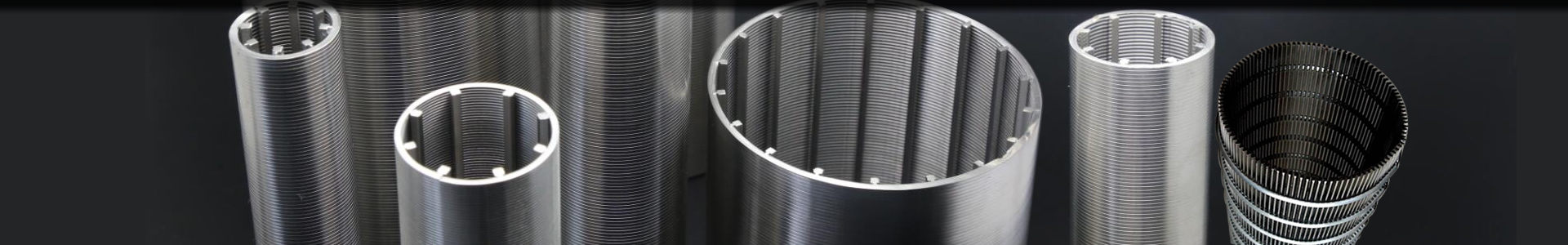

- Cylindrical Wedge Wire

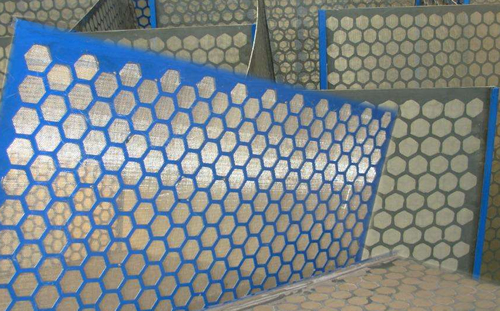

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

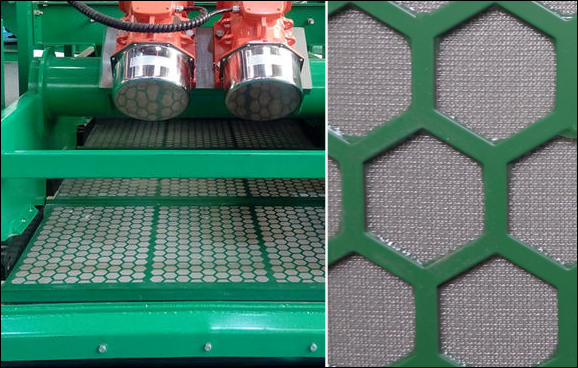

Oil Field Shale Shaker Screen, Vibratory Screen Filter Elements for Oil Drilling and Oil Refinery Plant

We supply metal wire vibratory screen supplied in standard accessories / OEM for Various Shale Shakers and Motion Solid Control Devices. Our vibrating shaker screen is mainly used in oil drilling mud process, coal mine and various ore dressing and other industrial sifting screening. The screen panels can be designed with multi-layer or single layer flat panels, with or without backing plate support.

Wedge wire filter elements for oil field equipment & spares

Service conditions:

Fluid: Oil emulsion( consists of 40% saline water and 60% crude oil )

Viscosity @ oper. Temp. = 3160 cps Density @ Oper. Temp. = 961 kg/m3 Flow

Rate = 354.16 m3/h Working temperature= ( min./ Nor. / Max. ) = 25/35/50

Deg.C Pressure drop across clean filter < 5 Kpa Max. allowable pressure drop

= 50 Kpa Slot size= 0.23 mm Selected :

Elements

Radial slot opening

Slot size = 0.23 mm

Wire width = 0.75 or 1.0 mm

Outside diameter = 30 mm

Length= 1000 mm

Max. Delta P 4.2 Bard

AISI 316L

Condition -clean pressure drop < 5 kpa

Shale Shaker Screen for Oil Drilling

| Description | P/N |

| Mesh 25 Or Equal | 01-03-25 |

| Mesh 39 Or Equal | 01-03-39 |

| Mesh 48 Or Equal | 01-03-48 |

| Mesh 86 Or Equal | 01-03-86 |

| Mesh 97 Or Equal | 01-03-97 |

| Mesh 118 Or Equal | 01-03-118 |

| Crown Rubber | 01-05 |

| Deck Spring (rear) | 01-07 |

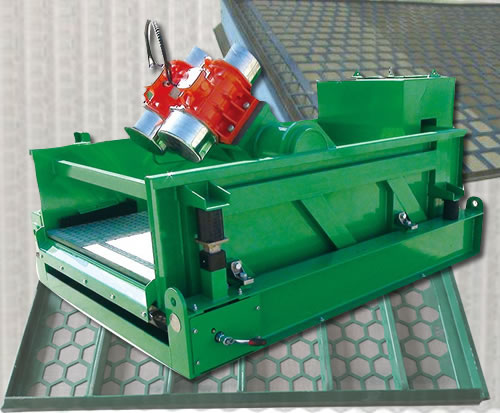

Shale shakers for Oil & Gas, Petrochemical

Shale Shaker Model-FLCC-514

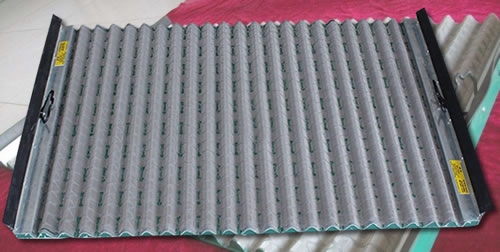

Screen Pattern- Multi layer wave

Mesh Sizes: 40x40,60x60,80x80,100x100,120x120

Oil vibrating shale shaker screen

Oil drilling filter vibrating flat shale shaker screen for solid seperation

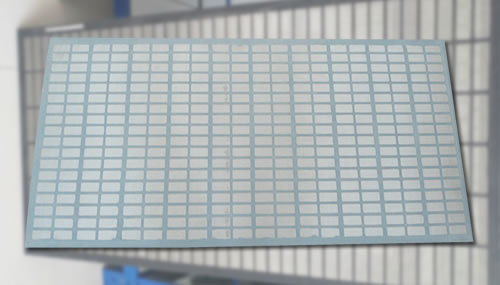

Hook strip Flat Shaker Screen for Oil and Gas

500 2000 hookstrip flat shale shaker screen multi layer metal mesh

1250 x 720mm iron frame shale shaker screen decks

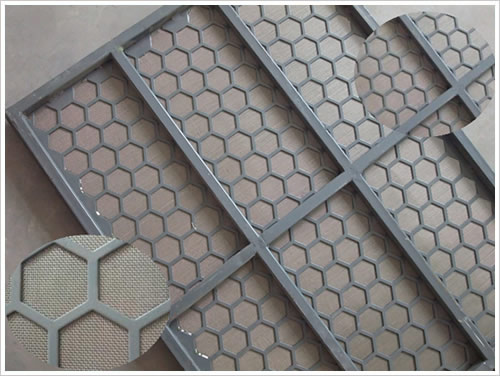

Composite Frame Square Hole oil field shale shaker screens

Shaker screen for solid control equipment

Waved type multi layer mesh screen for oil field and quarry screening uses

Oilfield Vibrating Shale Shaker

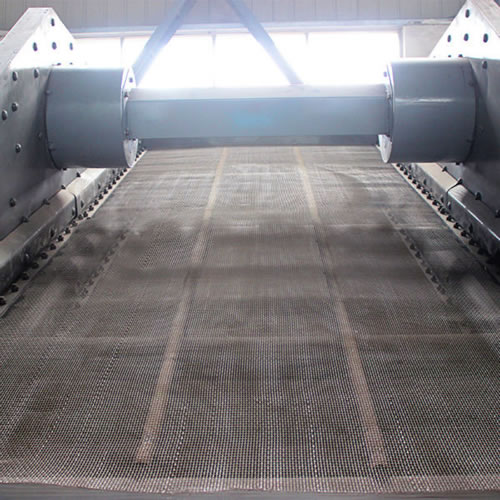

Multi-layer or single layer flat wire mesh screen panels for Oil Refinery Plant

Quarry multi decks vibrating sieve mesh screen with high strength, woven type

Shaker Vibrating Sand Screen Applied in Quarry

Quarry Mine Vibrating Shaker Screen

Gravel mining vibrating shaker screen

Varieties:

Vibrating shaker and sieve screen can be: crimped wire screen, mining screen and quarry screen made from metal wire mesh or polyester mesh fabrics to separate mixed material and to classify particle sizes.

Parts and Structures:

The oil vibrating screen is made with strips, frames and layers of wire screen cloths by welding or hooking or other forms of bonding. The Screen panels and plates can be combination of single-deck or multi-deck screen, so as to meet the requirements of a certain ore dressing process.

Strip or Frames: Hookstrip Flat Screen, Soft Screen, Framed Flat Screen, Framed Waved Screen, Hook strip Waved Screen.

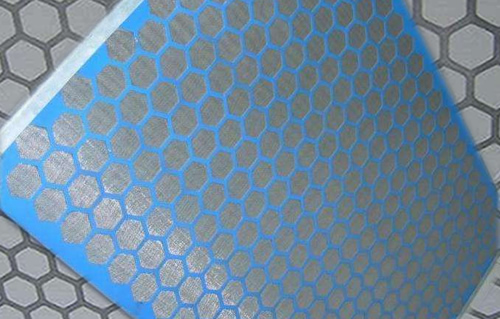

Multilayer Metal Screen Panels made with 304 Wire Cloth and Perforated Steel Backed Vibrating Sifting Screen

Wire Screen Fabrics Applied for Oil Field Vibrating Screen: Pre-crimped woven steel wire coarse mesh, polyester mesh fabric or micron slotted perforated metal plates, woven stainless steel mesh cloth.

Filter Mesh Cloth Ranges: 20mesh-275 Mesh

Common Size of the Screen Panels: 560*1800mm, 600*1800mm, 630*1250mm, 695*1050mm, 700*1050mm, 760*1830mm, 763*1115mm, 800*1250mm.

Materials:

Stainless steel 304l, 316l, carbon steel, polyester, nylon or dacron, rubber.

The materials shall be resistant to acid, alkaline, heat, corrosion, suitable for process of screening and filtering. Also wear resistance is very important for the screening materials as wear occurs badly on the panels due to rubbings between materials and panels during the screening process.

Plate: 2.0 mm ± 0.1 mm

Aperture: 40 * 40mm rectangular hole

1133 * 780mm * 20-325 mesh / 20 mesh Woven SS Mesh Screen with the upper mesh wire diameter: 0.08mm ± 0.01mm, aperture: 0.17mm ± 0.01mm; Lower mesh wire diameter: 0.32 mm ± 0.01 mm, Aperture:: 1.06 mm ± 0.01 mm

Features:

1. Tensioned mesh surface;

2. High damping capacity resulting in reduced noise;

3. Easy assembling and disassembling;

4. Good resilience leading to a higher bounce frequency of materials and increased screen efficiency;

5. Apertures of screen can be deformed within a certain limit, resulting in a reduced probability of aperture blockage by the material;

6. Screen panels and plates may be framed with different material in the pressure molding process, extending the service life;

7. The shale shaker screen for oil and gas industry can handle large liquid flow rate capacity;

8. Blinding resistance;

9. Durable & long lasting construction in drilling mud projects;

10. Different apertures of screen can be designed per the user's requirements.

Specifications for General Vibrating and Sifting Shale Shaker

| Vibrating 500/2000 shale shaker screen | 40mesh/20meshx700x1050 | ||

| 48-30D | 80mesh/20meshx700x1050 | ||

| 120mesh/30meshx700x1050 | |||

| 160mesh/40meshx700x1050 | |||

| 40mesh-200mesh stainless steel woven wire cloth for above | |||

| Vibrating 500/2000 shale shaker screen | 20mesh/12meshx700x1050 | ||

| 48-30D | 40mesh/18mesh/12meshx700x1050 | ||

| 100mesh/40mesh/20meshx700x1050 | |||

| 160mesh/60mesh/20meshx700x1050 | |||

| 200mesh/60mesh/20meshx700x1050 | |||

| 20mesh-200mesh ss woven square mesh screen for above | |||

| Three tier conglutination screen mesh | 40mesh/20mesh/12meshx715x1215 | ||

| 80mesh/40mesh/12meshx715x1215 | |||

| 120mesh/40mesh/20meshx715x1215 | |||

| 180mesh/60mesh/20meshx715x1215 | |||

| 20mesh-200mesh for above | |||

| Shale shaker screen | 40mesh/12meshx900x1146 | ||

| 80mesh/20meshx900x1146 | |||

| 140mesh/20meshx900x1146 | |||

| 20mesh-160mesh for above | |||

| Vibrating sieving mesh | NS-115/2 | 60mesh/20meshx1150x1000 | |

| 100mesh/20meshx1150x1000 | |||

Oil field replacement Shaker Screen

Repairable and Replaceable Mesh and Screen

Flat and framed plate screen panels are mainly used for Vibrating type shale shaker screen system with repairable plate screen panels.

Materials: Carbon steel and stainless steel

Standard sizes:

De- 48-30D

40mesh/20meshx700x1050

80mesh/20meshx700x1050

120mesh/30meshx700x1050

160mesh/40meshx700x1050

Available Mesh per inch: 40-200

Repairable- 48-30D

20mesh/12meshx700x1050

40mesh/18mesh/12meshx700x1050

100mesh/40mesh/20meshx700x1050

160mesh/60mesh/20meshx700x1050

200mesh/60mesh/20meshx700x1050

Available Mesh per inch: 20-200

Uses: Oil field screen parts.