PRODUCTS CATALOG

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Wedge Wire Screen Technical Informations -SS 304 Parabolic Wedge Wire with Apertures of 0.3mm, 3mm & 5mm

Technical Reference for Wedge Screens and Elements

Defining elements of Wedge Wire Screen

Material of construction:

Most common materials of construction:304 and 316 Stainless Steels

Other materials:321 and 347 Stainless Steels, Galvanized Steel, Duplex, Super Duplex, Titanium, other alloys.

Slot opening: size of largest admissible particle through screen

Very fine: Under 100 microns - Only available with the smaller range of profile wires. Open area becomes key factor

Fine:100 microns and larger - Choice of profile wires extends to full range for slot openings 500 microns and larger.

Open Area as % of screen surface (OA%): required flow through a unit of screen surface and maximum / minimum pressure drop.

Screen construction: relevant intervening forces which the screen will be subjected to. If there are no relevant forces, screen construction may be defined jointly by slot opening, open area, and available screen fabricating tooling.

Additional structural elements defined by application requirements (may be informed with customer's drawing)

Also available for significant orders:

Custom design of profile wire, support bar, and bar pitch

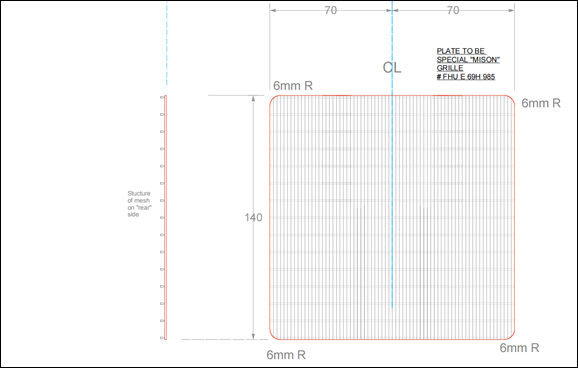

All dimensions in millimetres

Stucture of mesh on "rear" side

Mesh plate with radiused corners

"Flat" face to be mirror polished stainless steel 316L

Profile Types

Wedge wire is made of several profile types, offering a variety of features. Please choose different profile wire to meet your specific screen requirements.

Flat top wedge wire is the most commonly used profile wire giving good screening efficiency over the whole range in most applications. It is excellent for the de-watering of slurries and is extensively used in coal washers.

Conical top wedge wire is designed particularly for fine mesh screens for de-watering slurries.

Square top wedge wire is suitable for the larger aperture screens used with highly abrasive materials while Riffle top combines most of the de-watering qualities of both flat and conical top profiles and is also widely used as an attractive non-slip finish for drainage grids and walkways.

Wedge Wire Screen Features:

1. V-shaped profile wires have slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Wedge wire has low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Wedge wire screen has large open area with an effective flow, high yield and a low pressure drop (dP)

5. Economical: Flat and smooth surfaces can be cleaned very easily and therefore suitable for pre-served conditions and after cleaning exploitable for many times.

6. Long live: Welded at each intersection creating a strong and durable wire screen.

7. Wedge wire needs reduced installation costs.