PRODUCTS CATALOG

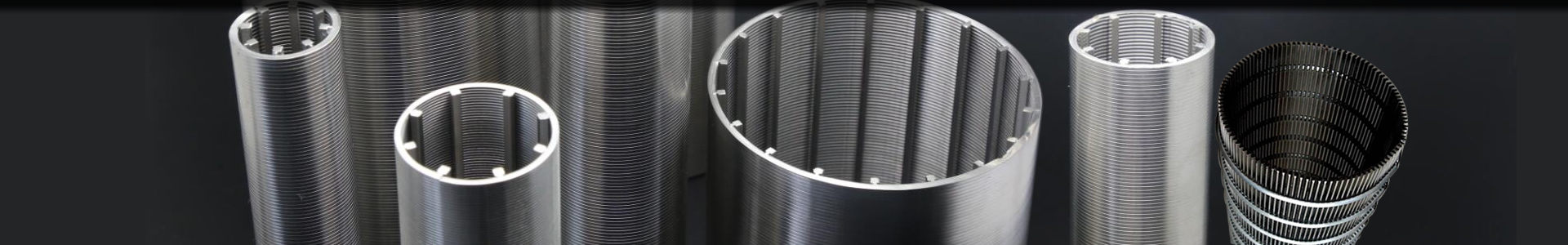

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

V Wire Screens- V Flat Profile Wire Screen,Tubular V Wire Screen

What is V Wire Screen? How is V Wire Screen Processed?

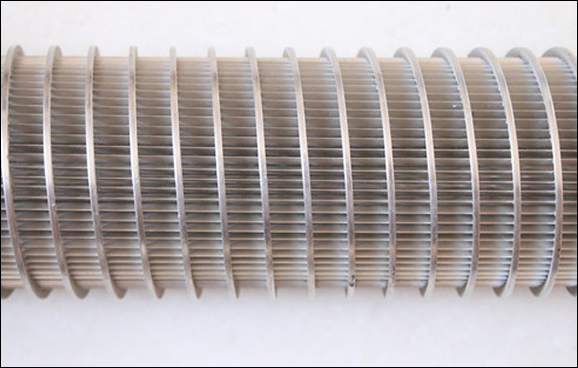

V Wire Screen is V formed wedge wire, fabricated by V profile wire, spirally wound around a longitudinal support rods. Each intersecting point of these wires is fusion welded, with an unique welding process for great strength of structure. The pitch of winding gives different spacing between two adjacent turns of wire which render passage for water to enter. The entire process is completed on fully computerized machines.

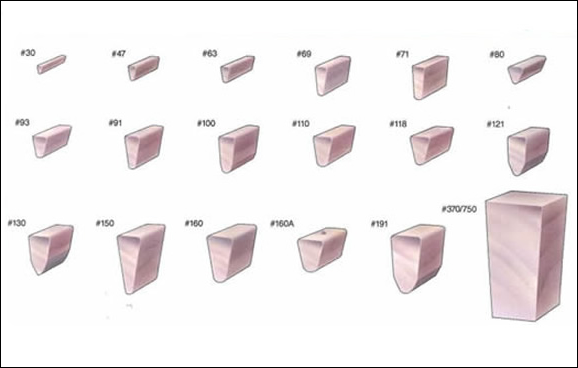

V Wire Profile:

V Wire Screen offering these advantages:

V Wire Screen has a continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone;

A "V" shaped profile wire can avoid clogging and ensure an uninterrupted flow;

A uniform and efficient well development due to the continuous slot opening;

Maximum effective flow area and operating efficiency;

All-welded construction offers greater strength over perforated tube, greater resistance to high operating pressures and temperatures, greater resistance to stresses of installation and cleaning;

Long service life;

Reduced costs;

Can be replaced;

Wide range of applcations.

Typical Specifications:

Diameter Available: 1.5", 2", 3", 4", 6", 8", 10", 12", 14"

Slot (mm): 0.15,0.25, 0.50, 0.75,1.00,1.50,2.00,3.00

Lengths: 6 Mts. & 3 Mts.

Material:

Low Carbon Galvanized Steel ( LCG ) and Stainless Steel ( SS-304 )

Application:

V Wire Screen is widely used in the field of process and engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

- Separating;

- Sizing;

- Straining;

- De-watering;

- Filtering;

- Drying;

- Water intake;

- Media retention

We supply following flat V wire panels and tubular v wire screens.

V-wire Screen and Machine Cut Screen - for equipment and brewery system manufacturer in North America

V-wire machine cut stainless 304 screens

SCREEN V-WIRE 0.028'' (0.7mm) X 101-3/4 DIA WITH 1'' FLAT BAR SUPPORTS

SCREEN V-WIRE 0.028'' X 89-3/4" DIA

SCREEN V-WIRE 0.028'' X 53.75" DIA

SCREEN MACHINE CUT 77.75" 3/16 PL SS316

SCREEN MACHINE CUT 96.75" 10GA SS316

Tubular V Wire Screen

Stainless Steel Wedge wire V wrap screen pipe/tube

3 inch,

with two width 0.015 inch and 0.020 inch

Material of SS 316 SS

With vessel size ID 2600 mm and T/T 4584 mm

Thickness 0.6 inch.

V Profile Wires Wedge Filter Screen

Material: stainless steel SS304, SS316

Screen mesh slots: 1mm

screen width: 2000mm

screen straight length: 1170mm

screen arc length: 1200mm

screen V profile wires: 2x3.5mm

screen T profile wires: 4x7mm

V Flat Wedge Wire Screen

Flat Wedge Wire Screen, one piece 57-1/2" O.D.

93V/177R With 0.030" slots, unframed.

304 ss construction.

Flat Wedge Wire Screen, one piece 47-1/2" O.D.

93V/177R With 0.030" slots, unframed.

304 ss construction.

Profile Wire and Rods for V Wire Screens

| Specification (Profile wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 |

| Specification (support rods): | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

| Note: other wires and rods available upon request | |

| Slot size | 0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material: | Low carton, low carton galvanized steel (LCG), stainless steel (304,316 etc.) |

| Length | Lengths up to 6 meters. |

| Diameter | ranging from 25mm to 800mm. |

| End connection | Plain beveled ends for butt welding or threaded |

V wire wrapped steel screen pipe