PRODUCTS CATALOG

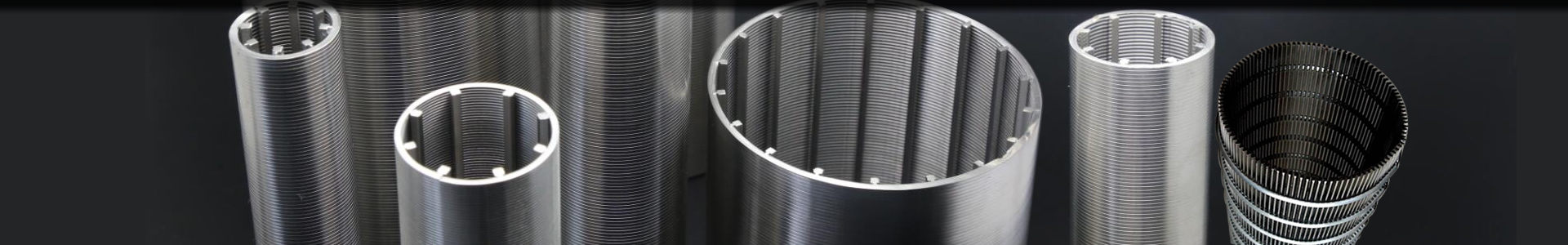

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Stainless Steel 304 Oil Well Screen

We are wedge wire filter provider to the oil and gas industry in the Middle East region as well as countries. Welded wedge wire oil well screens are designed for the typical oil well depths and consist of a perforated LCS base pipe and an outer wedge wire "jacket" in galvanized or stainless steel.

V wire wrapped well screens are designed for the typical oil well depths. It functions to control the sand in oil drilling hence also known as sand control screen.

Technical Information of Oil Well Screen:

Materials: 304 302 304L 316 316L stainless steel wire.

Common sizes

Diameters from 2 7/8" to 13 3/8".

Slot openings from 0.05 mm (0.002") up.

Lengths up to API Range III.

Threaded ends.

Processing and features:

The welded stainless steel oil well screen is made up of supporting rods and wire screening strips. The supporting rod can be round wire, triangular wire or trapezoid wire. The screening filter is made of triangular wire (V-shaped wire). Well screens have a structure and high opening area, as well as accurate slot dimension. In the same time, oil well screen have heat-resisting, anti-corrosive, good machine capability, long life span, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Styles of connection: by welding or by threaded male/female couplings.

Standard length for the well screen: 3m/5.85m. Sizes can be made according to the customers’ requirement.

Oil well wedge wire screen - stainless steel mesh filters

Stainless steel perforated pipe for well screen parts

Wire Wrapped Sand control screen used in API pipes

Welded Wire Wrapped Pipe Screen is used for reliable sand free production for either vertical or horizontal oil wells. Wire Wrapped Screen has a maximum micron open area by utilizing an

accurately controlled gauge as low as 0.003". The slot or gauge spacing of the Wire Wrapped Well Screen is permanent.

There are no solder strips, weldbeads, or lugs to block the fluid flow around or through a Wire Wrapped Screen. The large inlet area allows higher production rates with lower entrance velocities and minimal pressure drop.