PRODUCTS CATALOG

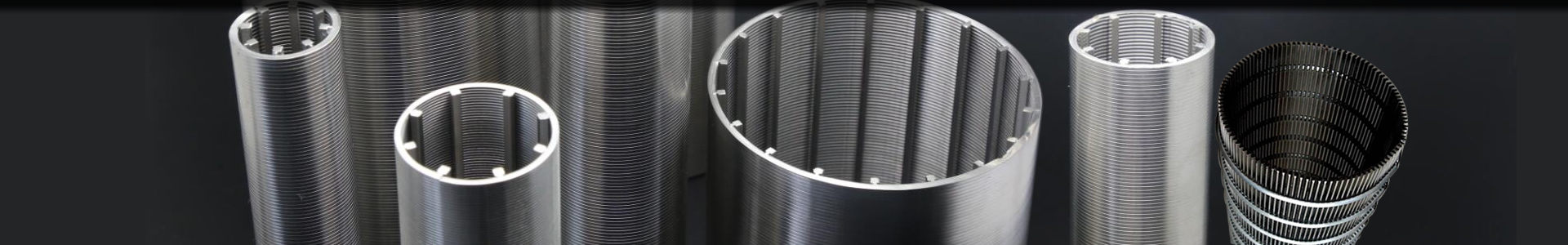

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Looped Wedge Wire Screen for Industrial Uses - Wire Screen of Looped Profile Wires

Atlas is a manufacturer of looped wedge wire made in stainless steel 304, 316 and mild steel as well as welded wedgewire.

Looped wedge wire screen is a type of steel mesh with a looped wire structure, supplied in different patterns and sizes, often used for filtrationand dewatering applications.

Welded Wedge Wire or Looped Wedge Wire

Compared to welded wedge wire, looped wedge wire has greater flexibility, which allows it to conform to different shapes and sizes. Additionally, looped wedge wire screen does not require as much welding and can be used for more applications.

Material for Producing Looped Wedge Wire

Looped wedge wire screens are typically made from stainless steel, but they can also be produced from other metals such as aluminum, galvanized steel and brass. The choice of material will depend on the application and environmental conditions they will be exposed to.

Main application of Looped Wedge Wire

The main application of looped wedge wire is for filtration and separation. It can be used for a variety of applications such as sieving, sorting, and straining, can also be used in mining and mineral processing, water treatment, food and beverage processing, and even in the construction industry.

We supply following standard and custom looped wedge wire screens:

Looped wedge wire screens come in a variety of sizes, shapes, and configurations. Common specifications include wire diameter, loop size, and opening size. The wire diameter typically ranges from 0.5mm to 4mm, the loop size from 5mm to 40mm, and the opening size from 0.6mm to 3.8mm.

Looped Wedge Wire ( Stainless Steel Corrosion Resisting)

| Length | Width | Slit |

| 700 | 600 | 0.35 |

| 830 | 580 | 0.50 |

| 1300 | 700 | 0.75 |

| 790 | 570 | 1.00 |

| 1000 | 450 | 2.00 |

| 1320 | 400 | 1.00 |

| 850 | 600 | 1.00 |

Slot direction parallel to the long side

Material: stainless steel, corrosion resisting

Wire profile as seen on design or approximate

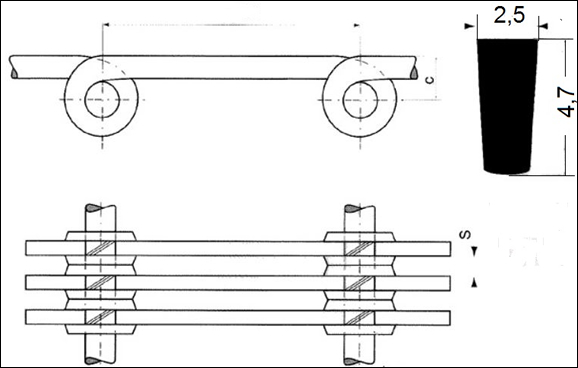

Comparing looped wedge with welded wedge, drawing reference:

| length | width | slit | pieces |

| 700 | 600 | 0.35 | 30 |

| 830 | 580 | 0.50 | 50 |

| 1300 | 700 | 0.75 | 23 |

| 790 | 570 | 1.00 | 84 |

| 1000 | 450 | 2.00 | 48 |

| 1320 | 400 | 1.00 | 56 |

| 850 | 600 | 1.00 | 176 |

| Slot direction parallel to the long side | |||

| Material 1.4301 (stainless steel, corrosion resisting) | |||

| Wire profile as seen on design or approximate | |||

| Length | Width | Slit |

| 750 | 600 | 0.50 |

| 750 | 600 | 0.75 |

| 750 | 600 | 1.00 |

| 1200 | 600 | 1.50 |

| 1500 | 1000 | 2.00 |

| 950 | 630 | 1.00 |

Slot direction parallel to the long side

Material 1.4301 (stainless steel, corrosion resisting)

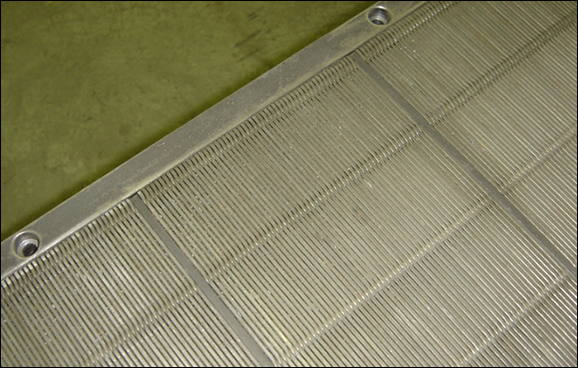

Looped Wedge Wire Screen and Sieves for rinsing coal

Wire and Chrome Segments for Vibrating Screens

The wires are wrapped around a rod D= 8 mm.

Chrome sieve segment:

Looped wedge wire from a round wire,the loops at a set pitch of 50mm.

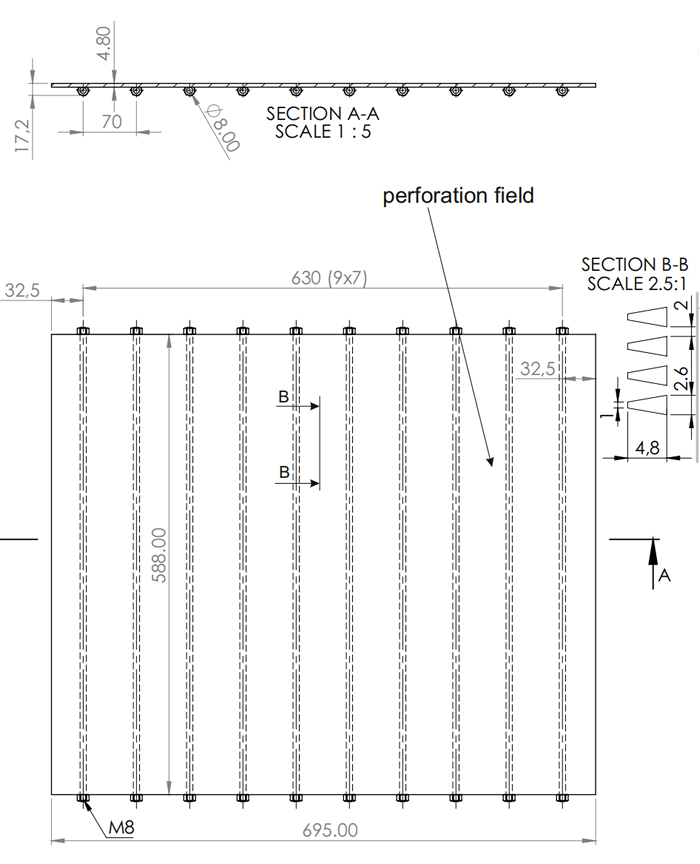

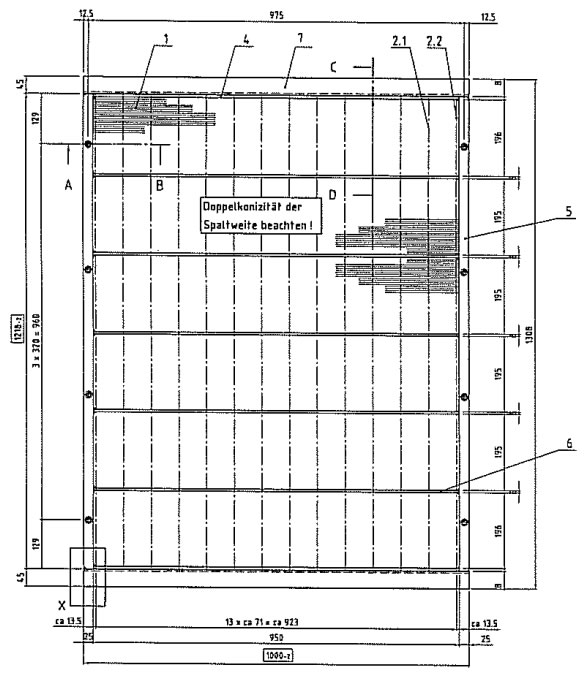

Wedge Wire Screens of Looped V Wire, for solvent extraction plant project

Data and drawings:

Wedge wire screens made of looped profile wires with edge reinforcement

Material:

Profile wires and cross bars

Edge reinforcement: St. 37K

Reinforcement rails : St. 37Kt

Wedge wire screen drawing:

Profile : 34Wa 34Wa 34Wa

Slit width: 0.5-0.7 0.5-0.7 0.5-0.7

Cross bar pitch : 70 mm 70 mm 70 mm

Length in slit direction : 1000mm, 750mm, 500mm

Width over frame without angle : 1218mm 1218mm 1218mm