PRODUCTS CATALOG

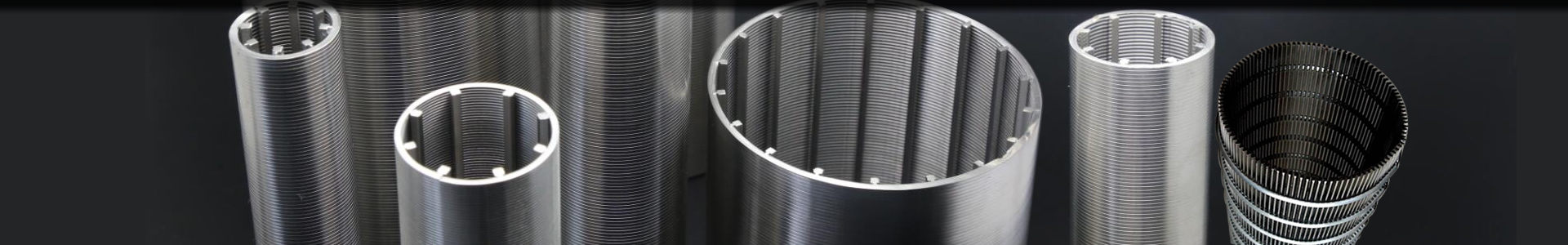

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

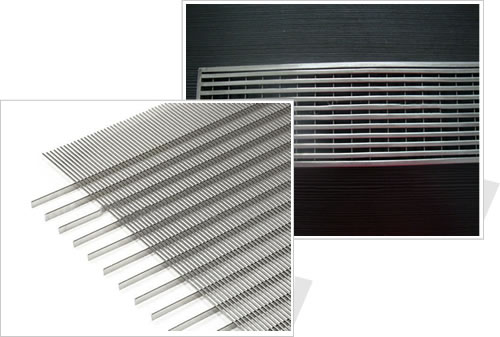

Stainless Steel Wedge Wire Grilles for Architectural Decoration - SS Circular Grilles and Flat Grilles

Stainless steel (grade 304) wedge wire grilles are becoming favorite components of architectural designers. Combined with perforated metal panels or expanded metal sheets, the wedge wire grilles can be fabricated in modern airports and other buildings internal and facade cladding.

Stainless Steel (grade 304) Wedge Wire Grilles

Wedge Wire Grilles for Architectural Cladding Project

Drawings showing a typical column cladding detail.

Stainless steel curved Grille (50% free area)

4 equal quadrants of grille fixed via a continuous angle back to bracket.

Free area/performance

50%

50%

perforated metal curved sheeting

4 equal quadrants fixed to back of SS Grille

Free area/performance to requirements

Wedgewire slot Grille & perforated metal fully accessible for cleaning.

SS Sleeve, the internal diameter to suit schedule

Continuous vertical angle fixed back to packer and bracket to allow fixing

Continuous vertical packing piece between bracket and angles

Cladding fixing brackets

Fixed back to Column at 600 centres

Sized to support cladding and diameter per required

Structural Column

SS section fixed back to cladding bracket

The design for the decorative metal grilles is as follows:

-

Grille design - Slots to run horizontally.

- The Stainless steel grille is to provide 50% free area for the movement of air.

- The grill is to be fabricated in solid stainless grade 304 sections with a 240grit brush finish; grain of finish to run with the long horizontal length of the steel.

- Rods are to be welded to the rear face of the profiles and to run vertically set out with 50mm centres.

- The ends of the panels are to have a closure strip secretly welded to the profiles at the outside edge. The strip (20x2mm 304 grade Stainless steel) is to sit proud of the horizontal profiles by 2-3mm.

- On the rear face of the metal grill is to be a powder coated perforated metal panel. Perforated panel is to be fixed to the wedge wire metal grill via a mechanical fix to rods.

- Fabrication method should ensure a consistent parallel gap and tangential grid between Rods and profiles.

- Distance between back face of profiles and perforate panel is set by air pressure requirements.

- Wane panels will not be accepted.

- All panels will be subject to approval

Details Specifications of The Wedge Wire Metal Grilles for the Cladding Uses:

Circular Column Stainless Steel 304 Grilles:

960mm dia x 3200mm high

920mm dia x 4900mm high

920mm dia x 4450mm high

920mm dia x 3200mm high

870mm dia x 4600mm high

510mm dia x 3200mm high

700mm dia x 3000mm high

Grilles made in 4 quadrants.

In addition to the circular columns, we also supply flat rectangular shaped stainless steel grilles as follows:

Flat rectangular stainless grilles:

3000mm wide x 900mm high

3000mm wide x 2400mm high

2000mm wide x 2400mm high

1800mm wide x 2400mm high

3600mm wide x 900mm high

1200mm wide x 900mm high

1115mm wide x 3400mm high

1500mm wide x 2400mm high

2300mm wide x 2400mm high

2000mm wide x 150mm high

The specification for the rectangular grilles is the same as the circular columns.

A light perforated metal panel can be fixed to wedge wire grille according to construction requirements.

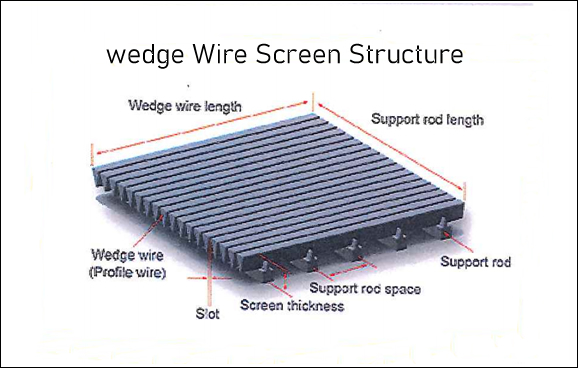

Wedge wire / profile wire structure for the mesh grilles:

Normal Surface Profile Wire

Wedge Wire:

| Section |  |

|

|

||||||||

| Width (mm) |

0.75 | 0.76 | 1.0 | 1.2 | 1.5 | 2.0 | 2.0 | 2.5 | 2.0 | 3.0 | 3.0 |

| Height (mm) |

1.35 | 1.5 | 2.0 | 2.3 | 2.5 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 |

Support Rod:

| Section |  |

|

|

|

||||||

| Width (mm) |

2.0 | 2.0 | 3.0 | 3.0 | 5.0 | 5.0 | 4.0 | 12.0 | 15.0 | 25.0 |

| Height (mm) |

3.0 | 3.0 | 5.0 | 6.0 | 8.0 | 6.0 | 7.0 | 3.0 | 3.0 | 3.0 |

Wedge Wire Screens for Construction of Shade Plate

Atlas wedge wire is used in constructions, for building of shade screen plate. Our recent architectural project is to supply to UK.

Material: Stainless steel 316L

Project: Details in PDF.

Stainless Steel Wedge Wire Floor Grilles

Outdoors dust proof stainless steel wedge wire entrance grilles