PRODUCTS CATALOG

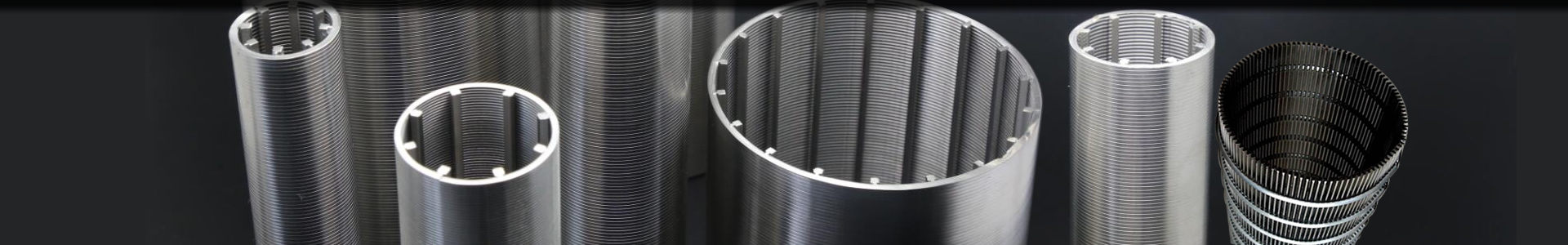

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Wedge Wire Screen Construction

Atlas wedge wire screen has mainly four wire constructions for control of water or liquid flow.

Wedge Screen Construction is defined by:

Selection from available profile wires

Selection from available support bars

Weldability between selected profile wire and support bar

Desirable support bar pitch (choices limited by available tooling)

Wedge screen constructions correspond with the follow drawings respectively:

1. Standard construction: The flow goes from outward to inside. Vertical rod support.

2. Axial wire construction: The water or liquid flows from outside to inside. Horizontal rod support.

3. Internal circumferential wire construction: The flow goes from inside to outside of the wedge wire screen. Outside rod support.

4. Inverwire construction. From inside to outside. Reverse flow.

Product Performance

1. Continuous opening has greatly increased the water flow area, so offers a better contact with the aquifer.

2. V-type profile of the structure to avoid clogging and ensure smooth flow.

3. Continuous long-term effective use of the pore.

4. Trapezoidal filter pipe offers a solid structure, high porosity, and accurate poring.

5. Trapezoidal wire filter pipe is easy for washing, long service life, safe, reliable, comprehensive and low cost.

Benefits of Wedge Wire Construction

1. porosity, high filtration tubes more suitable for the construction of high efficiency of water, oil and gas wells.

2. running cost is low porosity, high filtration tubes are more conducive to groundwater inflow, the abundant amount of water makes the water level drawdown reduced, thereby reducing energy consumption.

3. reducing the wear of the pump under the same conditions, the high porosity makes the groundwater in the infiltration of water treatment controls, the rate of penetration other than when the filter much slower and more so to avoid the sand in a larger pressure into the filter pipe, reducing pump wear and tear.

4. to extend the life of wells relative terms, infiltration of groundwater into the treatment of high porosity filter tube easier, the flow rate is low, to extend the life of wells.