PRODUCTS CATALOG

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

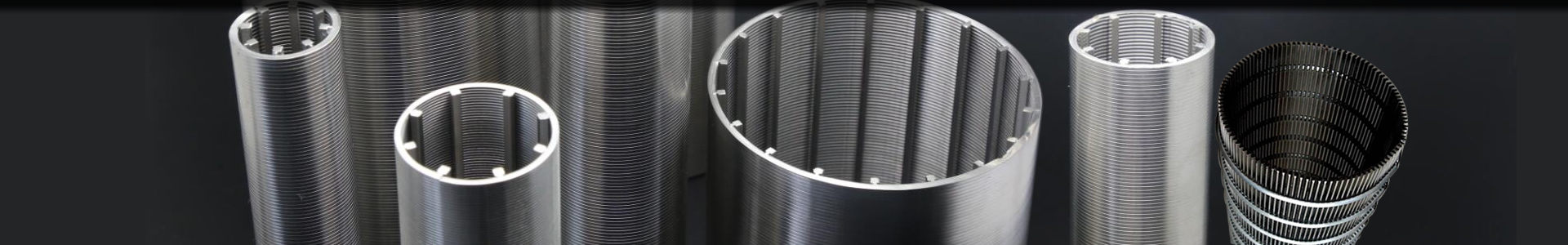

Wedge Wire Pipe Well Screen, Stainless Steel Wedge Wire Screen Pipe, Filter Pipe Screen

We export wedge wire pipe elements materials as per clients requirements. Wedge profile wire and the longitudinal support rods together forms a pipe filter suitable for well screen. So wedge wire pipe well screen has sturdy construction and good mechanical property. It is used to prevent sands from entering the water.

Structure of Wedge Wire Pipes:

The V wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.

The V-shape section plane can avoid blockage and make sure of the unimpeded water. The consecutive slot has more open area, and it can reduce the speed of the water entering to avoid the sand entering the pipes under the great pressure, so it can filter sand better. Meanwhile, the slot of wedge wire pipe can change according to the real condition of the earth.

Wedge wire pipe screen is a kind of water filter tubing which can be used with the deep well pump, water diving pump, also may used in the water-treating equipment, the environmental protection, the water desalination treatment, running water treatment, water softening treatment, the petroleum industry.

Wedge wire pipe:

230mm length

108mm ID

Bottom with 5mm blank flange

Top with 30mm width flange along circumference (5mm thickness)

2 mm slot size

We also supply:

1) E.C.W Wedge wire material.

Pipe shape

48"OAL 58V98R with 0.012" slots, 304SS construction,48" long

2) SS Wedge wire screen well pipe for the following sizes:

Range 50 NB to 300 NB (SS 304/304L/316/316L/LCG)

Note: Slit size will be from 50 micron to 1000 micron.

per meter basis with both end ACT API Coupling

3) wedge wire screen pipe

Diameter: 6" (150mm)

Sieve: 3mm

Length: 6 m ea

Material: SS316

4) 8" Wedge Wire Pipe

Wedge Wire Pipe - diameter 8" - length - 30 meters.

Slot opening size - 2 MM & 2.5 MM.

Material of construction - Carbon Steel & SS304.

1. Diameter: 50mm or 2"

2. Overall Length: 1200mm

3. Screen type: Normal external radial wire

4. Flow direction: From outside inwards

5. Medium: Water and sand

6. Screen aperture:0.25mm or similar

7. End 1: Open

8. End 2: Male pipe-thread DN50 (50mm) or 2" NPT

Advantages

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

5. Long live: Welded at each intersection creating a strong and durable screen.

6. Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Technical Parameter of Wedge Wire Screen Media for Pipe Filter

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

| Specification (wedge wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Specification (support rod): | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request | |

| Slot size: | 0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material: | galvanized low carton (LCG), stainless steel (304,316 etc.) |

| Length: | up to 6 meters |

| Diameter: | from 25mm to 1200mm. |

Packing details:

Single with bubble bag and then in wooden case(fumigation certificate).

Each case is clearly marked with:

Name & identification mark of manufacturer

Batch number

Date of manufacture

Material

Safe heating & application temperature

304 stainless steel rewind wedge mesh pipe, wire wound screen

SS 316L water well filter wedge wire screen pipes