PRODUCTS CATALOG

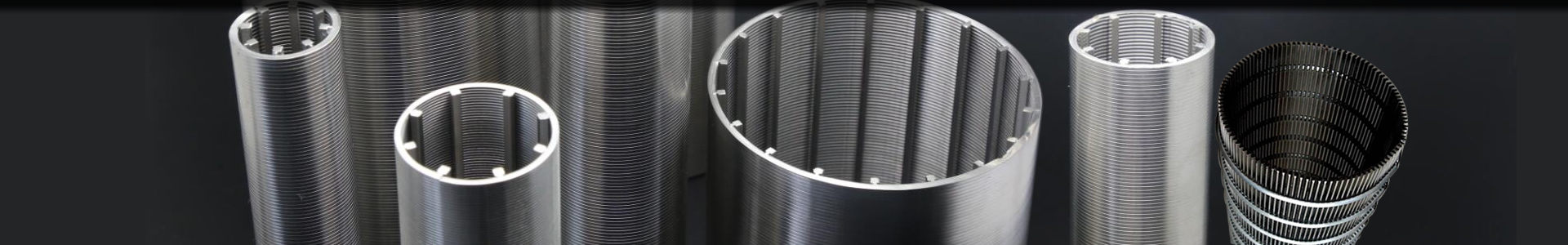

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Wedge Wire Screen for Rotary Sifters, 150 micron Stainless Steel Wedge Wire Sifter Screen Mesh

Atlas supplies metal wire sifting screens used for centrifugal rotary sifters used in mining as well as other sifting machines.

Wedgewire Sifter Screen

Wedge sifter screen, fit for Kasons model YO-SS sifter

Opening: 150 micron stainless steel sifter

Reasons to Choose Wedge Wire Sifter Screen:

Four types of mesh screens are available for centrifugal rotary sifters including: high tension nylon mesh, woven wire screen, perforated panels and wedge wire.

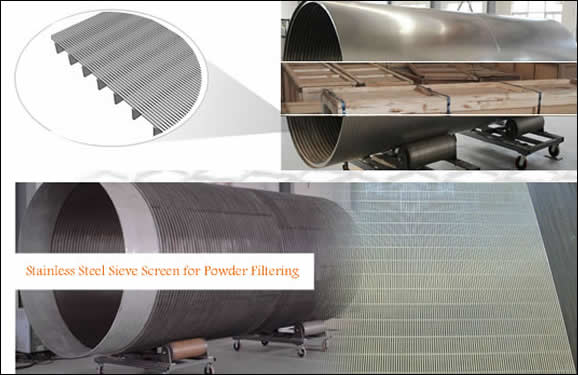

Among the four types, wedge wire screen is most welcome with the following features: precise opening, welded construction, metal materials and shape keeping. This screen has low requirements for the moisture content of the processed materials, suitable for Sieving fine particles of materials under various conditions.

Compared with the nylon mesh, the metal wedge wire is flat and easy for use. Compared with woven wire, the wedge wire has welded structure that ensures good strength and durability, it does not change form and will keep precise sifting function under great pressure. Also, the metal slots (stainless steel) wedge wire sifter screen surface is self-cleaning. Compared with strong perforated metal screen, the wedge wire sifter screen shows greater strength with backing of metal bars.

Stainless Steel Wedge Wire Sifting Screen is three-dimensional and multi-functional screen for powder and liquid sifting. Generally it has three main applications: classification or sieving; solid-liquid separation or filtration; washing and cleaning. Metal sifter screen is widely used in powder retaining, filtering and quarry mine development, building materials, chemical, abrasive, ceramic, pharmaceutical, papermaking, metallurgy, mining, food industry, etc.

Sifter sieve screen is made of multilayer and high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. This kind of screen has long stream line, many specifications and clear screening for different specifications.

It has features of durable structure, good strength, high screening efficiency, low noise, convenient maintenance, safe operation, easy to operate, easy to change the screen cloth (3-5 minutes), easy to clean, automatic discharge of impurities and coarse materials, continuous operation.

Sifter slots wedge wire screen media:

| Screen surface specification (mm) |

Layers | Sieve pore size (mm) |

Max feed size (mm) |

Capacity (t/h) |

Motor power (kw) |

Sifting frequency (r/min) |

Double Amplitude (mm) |

| 1200×3700 | 2 | 3-50 | 200 | 30-100 | 5.5 | 970 | 5-9 |

| 1200×3700 | 3 | 3-50 | 200 | 30-100 | 7.5 | 5-9 | |

| 4800×1500 | 2 | 3-100 | 400 | 30-275 | 15 | 970 | 5-9 |

| 4800×1500 | 3 | 3-100 | 400 | 30-275 | 15 | 970 | 5-9 |

| 4800×1500 | 2 | 3-100 | 400 | 56-330 | 18.5 | 970 | 5-9 |

| 4800×1800 | 3 | 3-100 | 400 | 56-330 | 18.5 | 970 | 5-9 |

| 4800×1800 | 4 | 3-80 | 400 | 56-330 | 22 | 970 | 5-9 |

| 6000×1800 | 2 | 3-100 | 400 | 65-586 | 18.5 | 970 | 5-9 |

| 6000×1800 | 3 | 3-100 | 400 | 65-586 | 22 | 970 | 5-9 |

| 6000×1800 | 4 | 3-100 | 400 | 65-586 | 30 | 980 | 5-9 |

| 6000×2100 | 2 | 3-100 | 400 | 81-720 | 22 | 980 | 5-9 |

| 6000×2100 | 3 | 3-100 | 400 | 81-720 | 30 | 970 | 5-9 |

| 6000×2100 | 4 | 3-100 | 400 | 81-720 | 30 | 980 | 5-9 |

| 6000×2400 | 2 | 3-150 | 400 | 100-810 | 22 | 970 | 5-9 |

| 6000×2400 | 3 | 3-150 | 400 | 100-810 | 30 | 980 | 5-9 |

| 6000×2400 | 4 | 3-150 | 400 | 150-850 | 37 | 980 | 5-9 |

We also supply other types of sifter screens mesh:

Sifter Screens Mesh ( Woven Type)

Sifter Screen Mesh, SS, #16, 3X100FT

Material: Stainless Steel

Screen panel size: 4x8ft

Mesh: 8

Mesh: 10

Mesh: 12

Mesh: 14

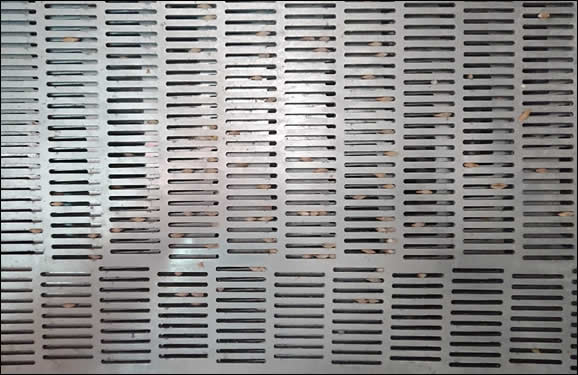

Hammer Mill Screens ( Perforated Type)

Dimension: 4x8ft

Material: BI perforated sheet

Thickness: 2mm

Size: 1.5mm, 2mm, 3mm, 4mm, 8mm

Sifter screen square mesh (Panels)

Length - 1650mm 2590 mm

Width - 400 mm 1240 mm

Size - 2 mm 3 mm

Nylon Mesh Screen for Rotary Flour Sifter

Flour sifter filter, simple in construction, thicker than 1/8 inch round cord material at end.

Construction and material details

Ends cotton or solid nylon material or Heavy cotton

Joint, solid Heavy Nylon /cotton material

25 mesh or 750-800 micron , 25 per inch mesh nylon wire or polyethylene wire cloth.

Inside diameter is 9.25 inches

Overall length is 14.5 inches from one end to another end.

Both end has 1.5 inch nylon/cotton felt pad with string inside

Open filer mesh area 11.5 inches length { 14.5 inches- (2 X 1.5 inches) =11.5 inches}

Flour sifter mesh size 25-30 mesh