PRODUCTS CATALOG

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

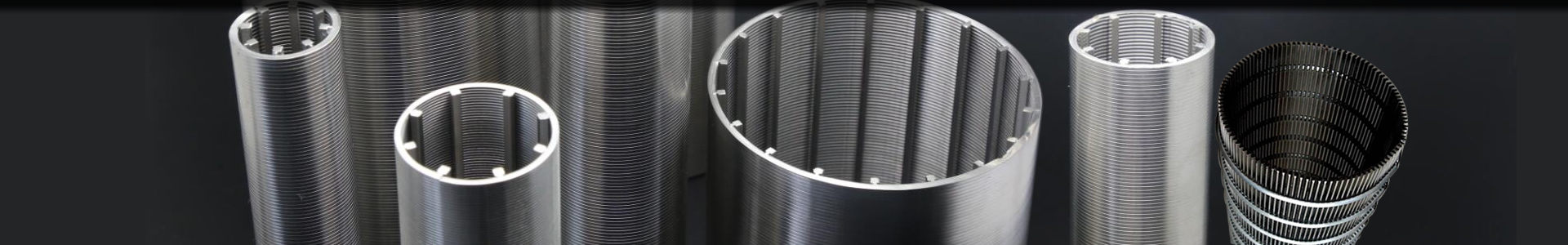

Re-rolled Screen with the Welded Bar and Micron Slot Size for Sand Control in water wells

This type of wedge wire well screen has a re-rolled construction. The spacing or gap between the support rod is precise. The sizes of the wire diameter and the rod depend on the depth of the well. The wire is v shaped axial wire, the support rod can be round, triangle shape. Axial wire diameters: 0.1mm, 0.25mm, 0.5mm, 0.75mm, 1.00mm.

Reverse rolled wedge wire screen materials can be low carbon galvanized (LCG) and stainless steel (SS).

The well screen's OD outside diameter is decided by the ID of the well and the casing pipe, the ID of the screen depends on the pump. The connection of the well screen is welding or thread.The unit length of the reverse rolled well screen is 2.9m or 5.8m. The carbon steel screen is galvanized to prolong the life of the screen.

Re-rolled wedge wire screen

Sizes in mm

Rerolled FITO construction, axial wire

Possible slot sizes: 0.1/0.25/0.50/0.75/1.00 mm

support rod gap approx 18.52mm

profile welded to the last wire to ensure wire does not get ripped out

Specifications:

Slot (mm): 0.05,0.1,0.25,0.50,0.75,1.00,1.50,2.00,3.00...60mm

Filtering method: From inside to outside

Standard length: 1m/5.85m or custom

Uses: Re rolled construction v wire screen tubing is suitable for water well drilling. It can be used in the water well, water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry and so on.

316L stainless steel wedge mesh V-type ladder type winding wire all-welded screen filter element

Wedge wire re-rolled screen for filter sand from water.

The re-rolled screen around 10 feet long with a 12 inch diameter opening. The wedge wire screen needs to be 4 feet wide by 8 feet long. Wedge dimensions 1/16 inch wide by ¼ inch long with a 13° bend in it.