PRODUCTS CATALOG

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

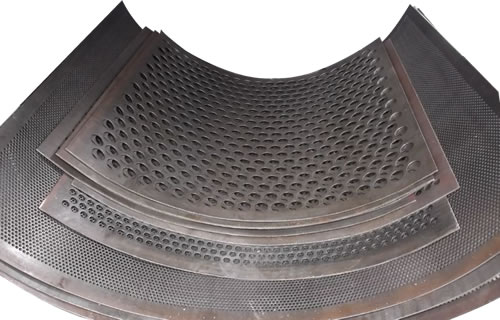

Sieve Bend Screen - Arc Curved Wedge Wire Screen Panels used for Conveyor Screening

What is Sieve Bend Screen?

Sieve bend screen, is a bend shape or arc shape metal screen with a tilted surface which enable it ideal filter material in conveyor screening process. Wedgewire sieve bends are curved mesh panels manufactured to suit a wide range of industries in Sugar, Coal Mining & Quarrying, Mineral Processing, Starch industry for fiber removing, Cement, and Industrial & Effluent Treatment etc.

Arc Curved Wedge Wire Plate Comparing with Flat Wedge Wire:

The tilted surface of the sieve bend screen offers greater screening and dewatering capacity compared with flat screen plate.

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

As slurry flows down the sieve bend screen each wedgewire's sharp leading edge slices away a thin layer of water and small-particle solids. Larger particles continue down the screen surface, with much of the liquid removed.

Wedge Wire Sieve Bend to Replace Traditional Sieve Bend of Perforated Screen

Wedge wire sieve bend has a robust and accurate wire structure, offering higher accuracy and strength above traditional Perforated Screen used as sieve bend materials under high pressure work environment.

Sieve Bend Features:

Energy Efficient

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the V wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

Made of SS "V" shaped, SS "COVEX" shaped wire rod, with unique welding process, offering great strength, precision, long service life.

We supply wedgewire screen bend with micron mesh sizes per the drawings, with required dimensions and mesh sizes.

Sieve Bend Screen

General specs

Screen width:12 inches

Screen length:17.5 to 18 inches long

Curve: approx 1 inch in 17.5 inches

Wire size: .040 inches

Wire Gap: .012 inches

Galvanized Sieve Bend

Galvanized metal sieve screen material with a 3/8-inch opening. Screen 5-feet x 5-feet, or othe sizes.

Wedge wire sieve with the following specs

Slot opening = .5mm

wire width = 1mm

Screen size:

562mm wide Slot openings are parallel to width

635mm long

Wedge Wire Sieve and Rotary Filter Parts

Sieve Bends and Round Barrel Sieve Mesh for Water Filtration products for USA

For the Round Barrel Sieve, 24 Inches length, with a Diameter of 16 or 18 Inches with water flow from the inside to outside.

Sieve Bend: width of 12 to 24 Inches and length 18 to 24 Inches.

Can be designed around the size of the Sieve

SS Wedge Wire Seive Bend Filter

Flow at least 3000 gph

Seperate solids down to 300 microns

To keep the seperated solids out of the water flow.

Sieve Bend Screens with no frames for prefilter

Stainless steel wedge wire seive 350mm wide by 600mm

Arc at a radius of 675mm, filtration to 300 micron.

Carbon Platelet Sieve Screen

Arc sieve products for carbon (coconut shell derived) platelet testing.

0.25mm Wedge Wire Sieve Bend

0.25mm wedge wire sieve bend approximately 300mm x 500mm.

Used for filtering

Sieve bend screens to pass 1000-2000 GPM at a 15-20% solid rate. 30 mesh wedge wire 2-3 mm thick to allow for sufficient wear.

Wedge Wire Sieve (Bend Screen Type )

30-600mm OD Wedge Wire Curved Plate

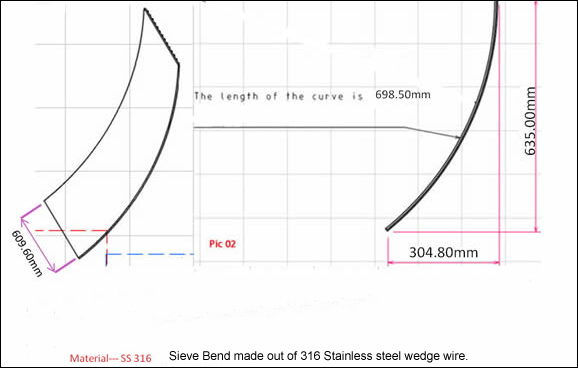

Sieve bend made out of 316 Stainless steel wedge wire for parabolic screen filter

Material-SS 316

Screen wire space .25mm (250 microns)

Screen Height-25 inches (635.00mm)

Screen Depth-12 inches (304.80mm)

Screen Length (curve)-27.5 inches (698.50mm)

Screen width 24 inches (609.60 mm)

Sieve Bend of rotary sieves for waste water

Wedge wire screen mesh: 0.02 mm, 0.03 mm, 0.04 mm, 0.06 mm, 0.08 mm, 0.1 mm

Material AISI304.

Application- component of rotary sieves for waste water(municial/industrial)

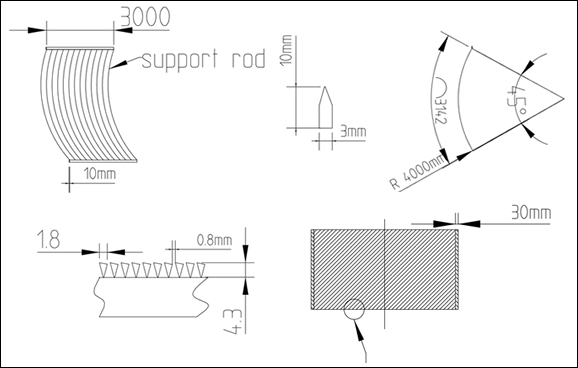

SIEVE BEND (DSM SCREEN)

SIZE: 3000 mm

WIDE X 4000 mm RADIUS X 45, (3142 mm ARC LENGTH), 63 PROFILE

Sieve bend screen panels for internals well screens, slot standard 457mm 6.35mm wall 350 grade pipe use in install a lot of large diameter temporary deep wells for construction site dewatering.

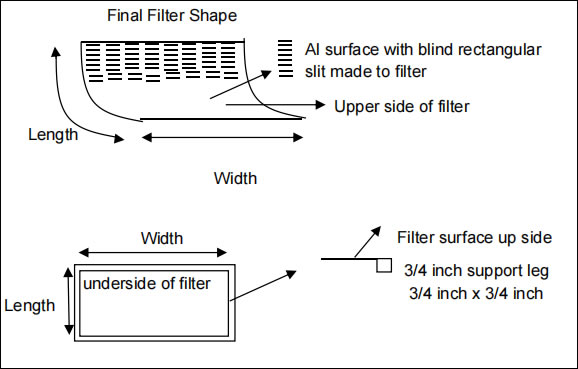

Wedge wire sieve bend screen

Wedge wire screen

with the following measures:

72.5 inch width x 62 inch length

72 inch width x 48 inch length

Curved bend sieve

Technical requirements:

SS AISI 316 material

1/16 inch or thicker wedges on all the sheet.

Gap separation on wedges for filtration purposes (25 inch mils)

Special curved bend screen for both sizes.

Wedges soldered with several transversal SS wires under them to hold them in place, with a separation of 1.5 inch on each wire, collocated under the wedges.

Additional a 1/4 x1/4 inch SS on the border under the wedges in order to support in place the filter.

Manganese Steel Perforated Screen ( Optional)

Steel grade under GOST2176-77 (similar to ZGMn13-1, ZGMn13-1-4, ZGMn13-2, ZGMn13-3);

Manganese steel;

Hardness: <220HB;

Diameter of bores: 40 mm;

Quantity of bores: 52;

Unpointed casting radius: 3-8 mm;

Weight: 30 kg