PRODUCTS CATALOG

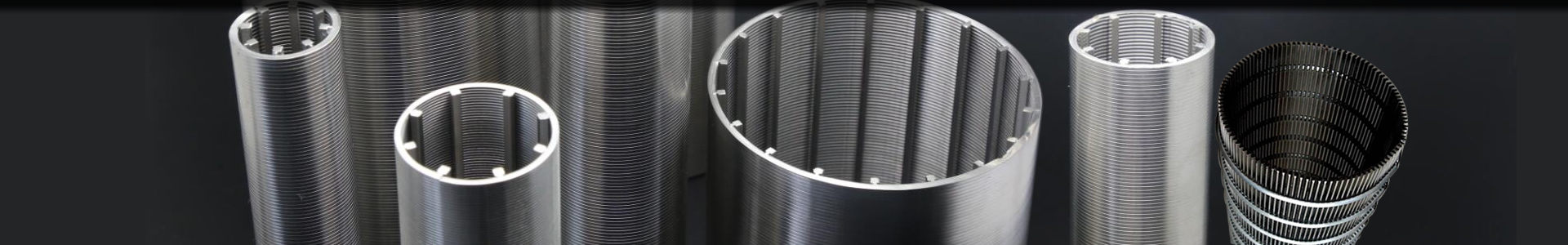

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Flat Wedge Wire Panels OAL (Slot Direction) and OAL (Rod Direction) in Galvanized Steel and Stainless Steel

Wedgewire panels are supplied in flat forms and curved panel forms. The flat panel wedge wire screen has high opening, lower entrance velocities and higher flow rates through the screen.

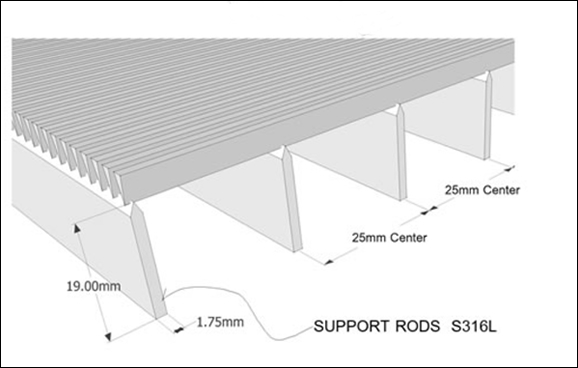

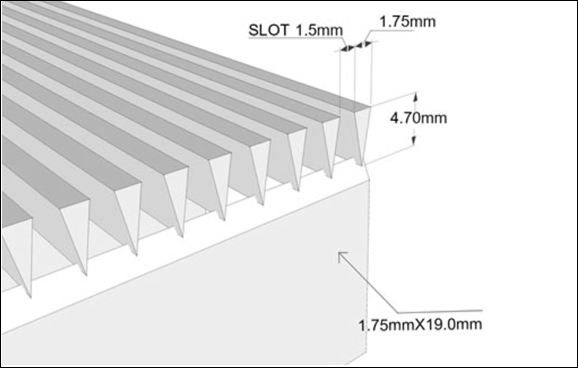

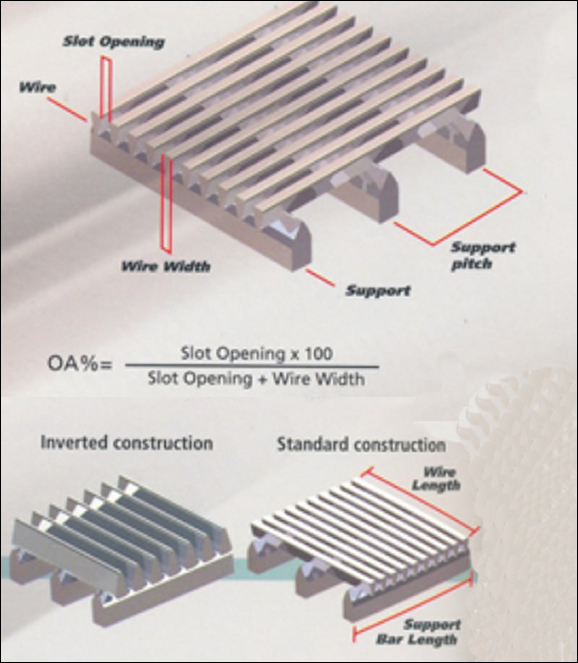

Structure of Flat Panel Wedge Wire

The mesh panels have continuous slot openings that widen inwardly. The panels are made by continuously winding a wrap wire onto a frame of support rods, featuring precision built, consistently high strength, precise slot openings and product durability.

Flat Wedge Wire Panels are produced in galvanized steel and stainless steel (304 and 316).

We supply wedge wire panels with standard specifications and similar specifications allowing flexibility in the design regarding slot width, support rod spacing, and wire profiles, and tolerances.

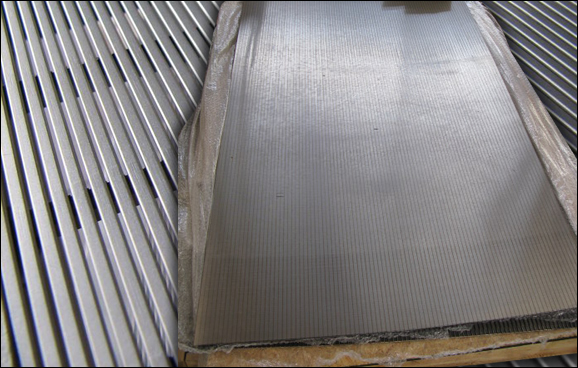

Wedge Wire Screen Flat Panels fitted in frames for Filter in Oil Base

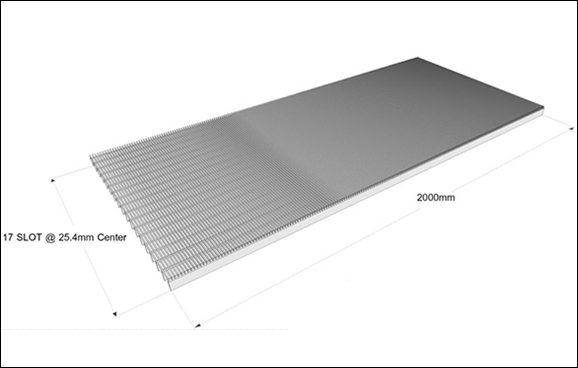

The specification as the following drawing.

Material: stainless S316L- support rod.

Length: 2000mm in one piece (no joining)- number of support rod slots: 17 slots.

One support rod is 25.4 mm center to center to the next support rod.

The thickness of the wedge wire and support rods can be different, the slot size per drawing- each support rod should be parallel to one another, and to the edge of screen.

Wedge wire slot 1.5 mm, the approximate dimension of wedge wire screen 433.5 mm x 2000 mm, the size 433.5 varies according to the thickness of wedge wire.

Flat Wedge Wire for Oil Clarification for Removing Solid Impurities from Product Oil

A screening system allows for the removal of bulk solids from the oil. This is done using gravity to minimize energy consumption.

To reduce solid contaminants in the product oil to less than 1% by weight.

Recommended Equipment: Centrifugal

Separation (decanters and centrifuges), Pressure Leaf Filters and Settling Tanks.

Screening Tank- Wedge wire 0.5 mm opening 09.10.19

Size approx 64" x 148" (1625 mm x 3759 mm L)- can be supplied at various sizes.

Flat Panel Wedge Wire ( Galvanized Steel)

Material: Low carbon galvanized steel

Slot size: 1.0 mm

Flat panel size: 1 meter x 50 cm.

Panel shape: Rectangular

Flat Wedge Wire Panels

Prototype panels with the approximate dimensions:

Panel size: a minimum of 862mm x 415mm

Material:304 or 316 Stainless Steel

Slot width:uniformly 25mm or 6mm running in the longer direction.

Two versions of the panels, one with 25mm slot width and the other with 6mm, preferably with wedge wire running in the longer dimension.

Wedge wire profile: approx. 4mm wide by 5mm high with a relief angle of 10-13(presumably from the 'Sb' shape series or if available a concave profile (to save weight)

Support rod spacing: 100mm

Support rod profile: 10mm x 2mm

Panels with the flatness tolerances.

Wedge Wire Screens Flat Panels OAL (slot direction) (304 Stainless Steel)

Specification

Flat Panels 289 mm OAL (slot direction) x 574 mm OAL (rod direction)

1.0 mm slot/#91wire/25x 2 support rods @25mm nominal centres f/w 40 x 3 flat bar SS surround frame.

Material all 304 Stainless steel.

Panel flatness +/-1.0mm

Diagonal Squareness:+/-1.0

Welding: no welding to top surface or wire.

Corners to be welded on inside and ground/polished on outside.

Slot requirements:1.0mm +/-0.05 average.

Min. 95% of all slots must lie between 0.90 mm and 1.1 mm

Min. 68% of slots lie between 0.95 mm and 1.05 mm.

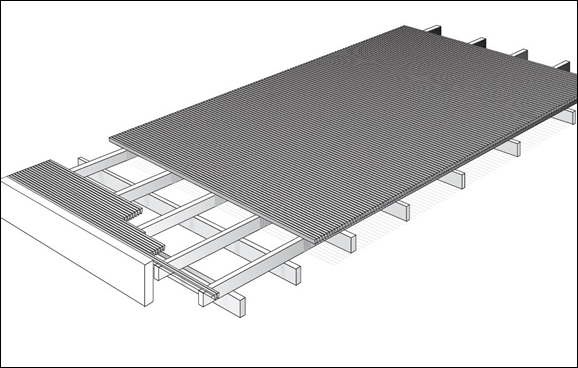

FLAT SCREEN

Dimensions, standard lengths

Standard Construction

Inverted Construction

Profile wire length: Maximum 2000 mm (79")

Support bar length: Maximum 3000 mm (118")

Wedge Wire Screen Flat Panels made of STAINLESS STEEL AISI 304, SLOT 0.50 MM, Panel size:2000X 2400 MM

Wedge Wire Flat Panel

Size (S/D) 1000mm wide x 800mm (rod)

Aperture 3.0mm

#118 Wedge Wire

SR250 support

Material Grade 304 SS

Supplied as a rough cut panel, slightly oversize

Wedge wire flat panel or curved using as a prefilter in aqua culture system

flow rate of 300gpm only seperating fish waste and excess fish feed. each filter system will start with the wedge wire to foam defractionator to bio filter. space available is 8ft in length and 4 ft in depth for each system.

FLAT SCREEN PANEL

Material: SUS304

Wedge wire Width:0.50mm.

Wedge wire Height:1.00mm.

Relief Angle:11degree

Support rods:1.3mm widht x 3.1 mm height @9mm. space between rod centers. (the size could be bigger but the spacing should be no larger than 9 mm.)

Frame: None

Size:850 (Slot direction) x 1400 mm.

Slot Opening:40Microns

90 Microns opening screen made with #30 wire (0.76 x 1.5 mm.), while other specs are the same.

Panel Screen Standard Specifications:

Slot size (mm): 0.025mm 0.10, 0.15, 0.2, 0.25, 0.30-3mm

Open area: up to 60%

Material: low carbon, low carbon galvanized steel (LCG) steel , stainless steel (304 etc.) Lengths up to 6 meters

Diameter: ranging from 25 to 800mm

End connection: plain beveled ends for butt welding or threaded

Material: Low Carbon Galvanized ( LCG ) and Stainless Steel (SS)

Slot (mm): 0.025 0.1、0.25、0.50、0.75、1.00、1.50、2.00、3.00 and so on.

Features:

Accurate slot gap, high efficiency performance, stable structure, anti-high temperature, anti-corrosive, good mechanical properties, long-lasting and durable, safe and reliable, various field can be applied.

Uses:

Wedge Wire Panel For Screening Tank

We offer rectangular panel using wedge wire with size 61" (1.54 m wide) x 121" (3.0 m) for screening tank. The slot runs in the direction of the length (3 meters) with an opening of 0.5 mm at least.

The application is for foots recovery tank Oil Mill.

The screens are fixed at the top of the tank and there is a scraper that continuously remove and scrape the foots.

The panel is flat as there is a scraper at the top that is moving at low rpm.

Material SS316 or SS316L.

Flat wedge wire sheet for drying floor

Wedge wire screen flat panel used in fertilizer, grain drying