PRODUCTS CATALOG

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

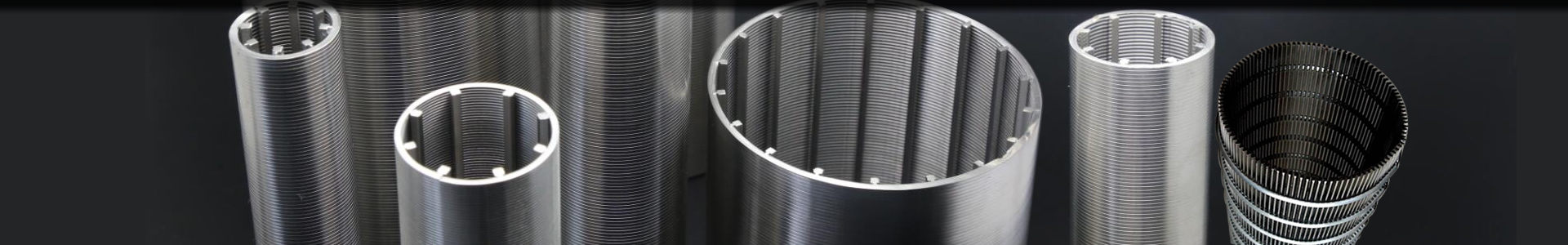

Wire Wrapped Wedge Wire Screen for Well Screen

Atlas Wire Wrapping Wedgewire Screen is commonly made with inverted wrapped V wire (mostly stainless steel ) welded to the supporting ss bar or rod. This type of wedge wire screen is mostly supplied in the form of screens cylinders / tubes used as pipe base well screen.

Screen Structures: The reversed wire rolled or wrapped wedge wire screen has the supporting rod outside of the filter cylinder or tube. This type of wedge wire screen goes from inside to outside, while another filter type is from outside to inside.

Material: Low Carbon Galvanized ( LCG ) and Stainless Steel (SS)

Slot size (mm): 0.05, 0.1, to 3.00..also achieved upon customer request.

Filtration Style: From inside to outside

Uses: Wire reversed wrapped wedge wire screen is mainly used for water well screens designed for depths of 100 m, 200 m, 350 m & 600 m.

Advantages of using Wire Wrapping Wedge Wire Screens:

When compared to conventional slotted sand control pipe, wire wrapped wedge wire screens have superior open area due to their continuous slot openings. This has 4 major benefits:

. Reduce energy consumption and increase water flow.

. Reduce erosion of entry surfaces and increase well life.

. Allow a uniform and efficient well development.

. Reduce significantly potential pump damage and subsequent maintenance costs.

Inverted Wrap Wedgewire Screen (Cylinder Shape):

Slot wire wrapped water-treating equipment screen

V Profile Stainless Steel Slot Wrapped Wedge Wire Screen Cylinder

Stainless Steel Wire Wrap Wedge Wire Filter Screen