PRODUCTS CATALOG

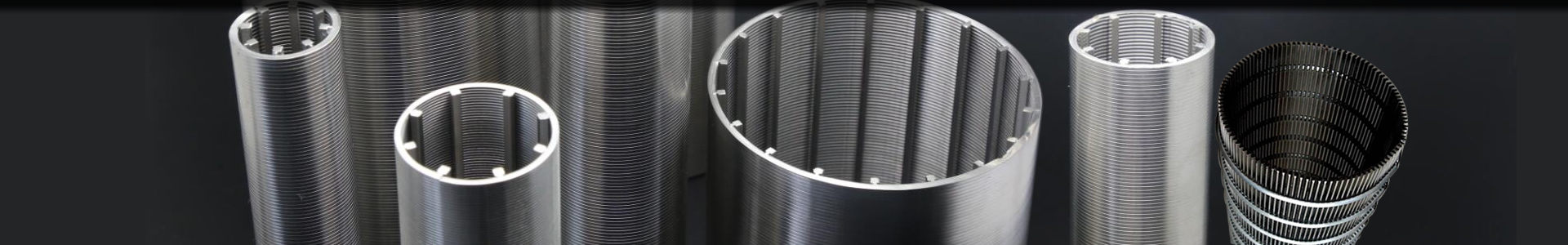

- Cylindrical Wedge Wire

- Shale Shaker Screen

- Precise Punched Slot Screen

- Wedge Wire Well Screens

- Rotary Drum Screen

- Sugar Mill Screen

- Wedge Wire Sifter Screen

- Re-Rolled Screen

- Internal Axial Wedge Wire Screen

- Wedge Wire Grilles

- Wedge Wire Basket

- Wire Wrapped Wedge Screen

- Welded Wedge Wire Screen

- Looped Wedge Wire Screens

- Sieve Bends

- Duplex Wedge Screen Cylinder

- DSM Screen

- Profile Wire Screen

- Flat Wedge Wire

- Wedge Wire Filter Elements

- Static Screen

- Intake Screen

- Wedge Wire Tube

- Woven Wire Mesh Screen

- Stainless Steel Wedge Wire

- Slot Wire Screen

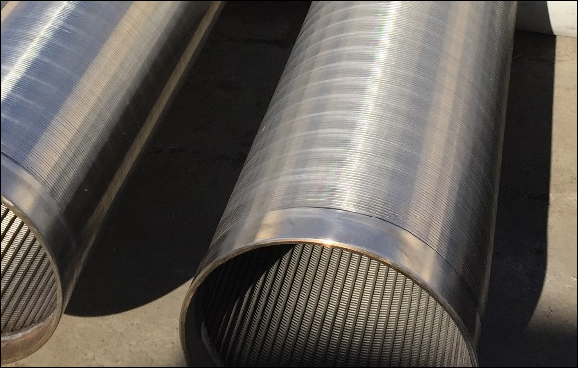

- Water Well Screen

- Oil Well Screen

- Vibrating Sieve Screen

- Run Down Screens

- V Wire Screen

- Mining Screen

- Crimped Wire Screens

- Trommel Screen

- 321 Wedge Profile Wire

- Suction Strainer

- Wedge Wire Screen Nozzle

- Wedge Wire for Bio Reactor

- Wedge Wire Pipe Screen

- Wedge Wire Barrier

- Slotted Bridge Water Weel Screen

- Wedge Wire Construction

- Wedge Wire Specification

- Sea Water Strainer Project

- Wedge Wire Screen Machine

Static Run Down Screen (Parabolic Screen Filter)

Run down screens offer a high capacity, cost effective method of solids/liquids separation utilizing stainless steel wedge wire as the screening medium.

Static Run Down Screen is well suited for food processing, the chemical industry and municipal water treatment. it's settles the problems relating to excessive solids contents in water or in other industrial or domestic liquids. With no moving parts, this screen has very low running costs, a long lifespan and is extremely low maintenance slurry flows over a wedge wire screen at up to 250 m3/hr. It can be set up to solve screening and pre-treatment problems, recovery of waste in shovelable form and water recycling.

We offer run down screens (D.S.M. type) complete with box and curved wedge wire screens to suit particular requirements of the customer in sugar, paper and pulp, water treatment.

Run Down Screens Designs

Each unit is designed to suit the specific requirements of the customer. Consisting of a basic outer casing, which can be manufactured in mild steel or stainless steel, each unit incorporates a distribution chamber and feed weir; over which the effluent passes onto the wedge wire panel which is set at right angles to the flow to enable the separating process to commence.

The separated solids collect on the lower half of the screen to drain and compact, they then slide by gravity onto a solids discharge chute.

The extracted liquid passes through the wedge wire into an underflow collecting tank, with a disposal outlet for either re-circulation or discharge.

Wedge Wire Run Down Screen Curved

Deep Well stainless steel wire wound screen for water